Hello there!

We’re back with another juicy edition of the Ostara newsletter! First up, a couple of quick Ostara updates…

Ostara Updates!

Now, for our topic for this month…

India’s first large-scale CNG programme kickstarted in 1998, in Delhi, after the Supreme Court of India then issued several directives centred around the clean fuel. Since then, almost a million automobiles in India have been successfully converted to CNG.

25 years later, a similar revolution is taking place in our country, but this time it involves converting to electric. With a total of 325 million vehicles on India’s roads today and the EV transition picking up steam, we believe it’s timely to think about converting the ICE vehicles to electric. And so, this month, we will be focusing on EV conversions in the Ostara Newletter’s EV Retrofitting edition.

What is EV Retrofitting?

EV retrofitting, or EV conversion, terms that are often used interchangeably, refer to the process of converting an existing gasoline or diesel-powered vehicle into an electric vehicle (EV). This process involves removing the vehicle’s internal combustion engine and replacing it with an electric motor, battery pack, and other necessary components to make it run on electricity.

The process of retrofitting can vary depending on the type of vehicle being converted, and the complexity of the conversion can depend on the age and make of the vehicle. Some companies specialize in EV retrofitting and offer conversion kits for specific models of vehicles.

What’s included in an EV Retrofitting Conversion kit?

Motor, Controller, Shunt

Transmission adapter kit, Charger, Chill plate

DC/DC converter, Throttle controller, Controller mount

Source: Inverted

A retrofitted vehicle uses almost the entirety of the body frame from the original vehicle. During its operation, it provides the same economic and environmental benefits which a new electric vehicle of similar specification provides, while also enabling the re-use of body parts and materials, which would be otherwise disposed of.

Types of Retrofitting

- Hybrid retrofitting: This entails adding an electric motor, battery pack, and related control systems to the vehicle’s existing internal combustion engine. The battery pack is charged through regenerative braking and adds extra energy when demand is at its highest, while the electric motor helps the diesel or petrol engine accelerate.

- Battery electric retrofitting: The internal combustion engine is removed and an electric motor, battery pack, and related control systems are installed in their place.

- Plug-in hybrid retrofitting: This involves retrofitting a hybrid vehicle with a bigger battery and a plug-in charging system, enabling the car to be charged from an external power source and run on electricity alone for more extended periods.

- Range extender retrofitting: This involves retrofitting a battery electric vehicle with a small gasoline or diesel engine that acts as a generator to recharge the battery pack when it runs low on charge. This extends the vehicle’s range and reduces the need for frequent charging.

- Regenerative braking retrofitting: This involves retrofitting a vehicle with a regenerative braking system that captures energy normally lost during braking and uses it to recharge the battery pack, increasing the vehicle’s efficiency and range.

Source: AFDC, Progressive

Conversion Process

The procedure for EV retrofitting can vary depending on the specific vehicle being converted and the conversion kit used. Generally, it involves the following steps:

- Vehicle evaluation: The first step is to evaluate the vehicle and determine if it is a suitable candidate for conversion. Factors to consider include the age and condition of the vehicle, its weight, and its overall design.

- Engine and fuel system removal: The internal combustion engine, fuel tank, and associated components are removed from the vehicle.

- Electric motor installation: The electric motor is installed in the vehicle, along with a motor controller, which regulates the motor’s speed and torque.

- Battery pack installation: The battery pack, which provides power to the electric motor, is installed in the vehicle. The number of batteries and their placement in the vehicle will depend on the specific conversion kit used.

- Charging system installation: An onboard charging system is installed, which allows the battery pack to be charged from an external power source.

- Wiring and controls: The vehicle’s wiring and control systems are modified to work with the new electric components.

- Testing and calibration: Once the conversion is complete, the vehicle is thoroughly tested to ensure that all components function correctly. The motor controller is calibrated to provide optimal performance, and the battery pack is tested for capacity and efficiency.

Regulatory framework for Retrofitting

ARAI (Automotive Research Association of India) has set out clear technical requirements for the approval of EV retrofitting kits. The Type Approvals for EV Retrofitting kits ensure the performance and safety of the retrofitted electric vehicles across a wide range of 2W and 3W categories, in addition to LCVs, Buses, Trucks, etc.

Type Approval procedure

The type approval procedure has 2 steps –

- Kit Component Level Approval: All the component aggregates being added to the vehicle, that can include traction motor, battery, inverter, wiring harness, connectors, state of charge indicators, and any other electronics such as vehicle control unit, on-board chargers, need to be approved first as a kit – for conversion into either a hybrid or pure electric vehicle.

- Vehicle Level Approval: The applicant must submit a retrofitted electric vehicle, the target vehicle in use, to ARAI for Type approval.

Once both the type of tests are conducted successfully, the Type Approval certificate is approved for the vehicle. Based on this, the kit manufacturer can appoint dealers to sell those kits for that particular vehicle. The dealer can retrofit on behalf of the kit manufacturer.

India’s Retrofit Standards:

- AIS 123-Part 1CMVR (Central Motor Vehicle Rules) Type Approval of Hybrid Electric System (HES) intended for retro-fitment on – (i) Vehicles of M & N Category with GVW <= 3500kg, (ii) L Category

- AIS123-Part 2CMVR Type Approval of Hybrid Electric System (HES) intended for retro-fitment on vehicles of M & N Category with GVW > 3500kg

- AIS123-Part 3CMVR Type Approval of Electric Propulsion kit Intended for conversion of vehicles for pure electric operation

Source: EVReporter

Policy Framework for Retrofitting

Several states in India have implemented policies to promote EV retrofitting. Here are some examples:

- Tamil Nadu EV Policy 2023 provides financial incentives of up to 15,000 rupees for retrofitting two-wheelers and up to 20,000 rupees for retrofitting of three-wheelers.

- In 2022, the Delhi Govt. announced faceless retrofitting services, a first in the country, which would allow owners to get their diesel vehicle to be retrofitted with an EV kit at their homes from an authorised dealer.

- Chandigarh Draft EV Policy 2022 states that a discount of up to 25,000 rupees can be availed if fuel goods & commercial vehicles are retrofitted with electric kits.

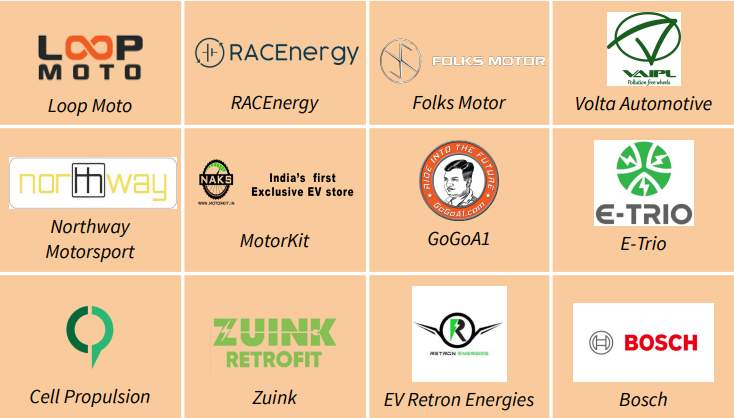

Select EV Retrofitters in India

Deals and Developments

Mar 2023: AMU Leasing, 3ev Industries, and 3eco Systems have announced a new collaboration to introduce India’s first commercially proven ICE-to-EV converted 3-wheel L-5N, e30x, for 3ev’s hyper-local transportation services in Mumbai.

Feb 2023: Karnataka Government wants to convert all diesel buses in the state to electric via retrofitment by 2030.

Jan 2023: Solapur-based Precision Camshafts Limited (PCL) will soon introduce retrofitted light commercial vehicles on electric drivetrains for on-road testing.

Jan 2023: Renault to offer retrofits for its most iconic cars to turn EV!